friction stir spot welding tensile test|friction stir welding tool material : discounter Benefitting from the newly developed temperature-controlled friction stir spot weld bonding process, we have elucidated the impact mechanisms of spot welding on the mechanical properties and fracture patterns of hybrid joints, both pre and post-adhesive curing. webBrazzers. Channel. Subscribe 2.4M. Add to friends. ️ BRAZZERS – You know who we are. Now discover why BRAZZERS is now and forever the best pornsite in the world. You want it all and we’ve got it. Discover the largest library of original content in the history of porn. See why all of the world’s top pornstars call BRAZZERS home.

{plog:ftitle_list}

WEBSweet exchange (Princess Connect! Re:Dive) [Otochichi] Subscription Mama! (COMIC Mugen Tensei 2024-01) [Chinese] [皇色汉化] nhentai is a free hentai manga and doujinshi reader with over 471,000 galleries to read and download.

refill friction stir welding

Paper Moisture Meter convenience store

Benefitting from the newly developed temperature-controlled friction stir spot weld bonding process, we have elucidated the impact mechanisms of spot welding on the mechanical properties and fracture patterns of hybrid joints, both pre and post-adhesive curing. Friction stir spot welding (FSSW) is a very useful variant of the conventional friction stir welding (FSW), which shows great potential to be a replacement of single-point .FSSW shows great potential to be a replacement of single-point joining processes like riveting and resistance spot welding. In this review work the testing method on weld joints produced . Friction stir spot welding (FSSW) is a very useful variant of the conventional friction stir welding (FSW), which shows great potential to be a replacement of single-point joining.

A novel method was introduced to model the stress-strain curve for friction stir spot welds under tensile-shear loading. The weld nuggets were considered as a rigid inclusion in a .

In this work, the tensile-shear mechanical behaviors of friction stir spot weld and adhesive hybrid joint were performed from both numerical and experimental viewpoints. Weld through (WT) and flow in (FI) processes were . Herein, microscale tensile testing of the joint interface was coupled with the macroscale fracture evaluation to elucidate the dominant factor of strength in dissimilar joints .Friction spot stir welding is realized by frictional heat. This welding technique is ideal for aluminium. It provides high quality connection with minimal residual stress and distortion. An .In this study, a simple, new, and inexpensive way was used based on the tensile test and stress concentration of the friction stir welding (FSW).

the "linear" friction stir welding (FSW) process, FSSW creates a spot, lap-weld without bulk melting. The appearance of the resulting weld resembles that of a resistance spot weld .

In this investigation, the dissimilar spot welds of AA2024-T6 Aluminium (Al) alloy and AZ31B Magnesium (Mg) alloy were fabricated using friction stir spot welding (FSSW) to counter over cracking, porosities, burning out issues, inferior joint strength and detrimental phase generation. The joint strength is a function of process parameters and can be maximized by . In this study, a modified version of friction stir spot welding (FSSW) is applied to join Al5083 specimens. In respect to conventional FSSW, this new method leads to better characteristics, finer grain sizes in the stir zone and higher mechanical properties. . The shape of the test pieces used in the tensile shear tests is shown in Fig. . Friction stir spot welding (FSSW) is one of the important variants of the friction stir welding (FSW) process. FSSW has been developed mainly for automotive applications where the different thickness sheets spot welding is .

refill friction stir spot welding

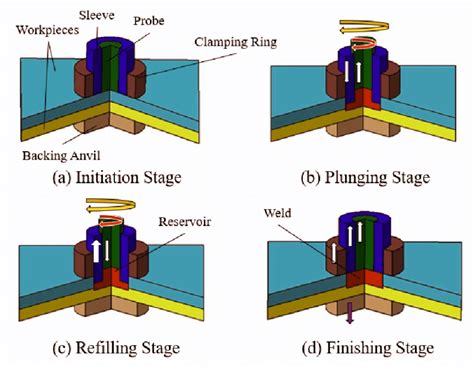

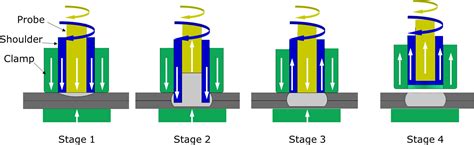

Friction stir spot welds (FSSW) are one variant of friction stir welding (FSW) where the traverse part of the FSW process is eliminated, i.e., the tool is only plunged into the material and retracted. Refill friction stir spot welding is a solid-state spot-welding technique suited to lap joining of thin aluminium sheets, including difficult-to-weld 2xxx series alloys that are prone to hot cracking during fusion welding processes. . Mechanical properties were established by tensile testing in accordance with BS EN ISO 6892–1:2019 , using . This paper investigates the fracture and damage of a single lap friction stir spot welding assembly formed from thin sheets of aluminium alloy 6082 T6. For fixed process parameters and tool geometry, two configurations are taken into account for the analysis of the global mechanical behaviour of the link. An experimental approach was carried out in order to . Friction stir welding (FSW) is a solid state joining technique developed for various types of materials such as metals and metal alloys [124].Furthermore, the joining processes of polymer materials with this method is quite possible [68].Unlike conventional fusion welding methods, the FSW takes place at lower process temperatures [55].Thus, it minimizes the .

Friction stir spot welding (FSSW) is a promising technique for joining thermoplastic materials, such as high-density polyethylene (HDPE). However, there needs to be more understanding regarding the effect of welding parameters on the weld temperature of FSSW joints in HDPE. The Taguchi method is used for a FSSW of HDPE sheets in the .

open literatures, the process features and variants, optimization of the testing method of the Friction stir spot welding process were summarized. Keywords: FSSW, Flexural behavior, Lap-shear tensile, Taguchi method and tool profile _____ I. INTRODUCTION Friction stir welding (FSW) process was well known invented by TWI in 1991 for aluminium . PDF | An Artificial Neural Network (ANN) model was developed to predict the tensile strength of the dissimilar aluminum weld using Friction Stir Welding. | Find, read and cite all the research .

Friction Stir Welding (FSW) is a solid-state welding process that involves the joining of materials without the need of a filler material or external heat source which is one of the main criteria to differentiate FSW from conventional welding processes [].FSW was invented in 1991, at The Welding Institute (TWI) in Cambridge England [].The FSW process involves a . Tool geometries and plunge depth play significant roles in the stirring process involved in micro-friction stir spot welding (µFSSW). These two variables affect the hook and joint formation, which influence the static strength and failure mode characterization of a single spot weld. The present work investigated the influence of tool geometry and plunge depth on . Refill friction stir spot welding (RFSSW) is a solid-state spot joining method that has attracted more and more attention from academia and industry at present. RFSSW has been successfully and widely used to weld aluminum alloys, magnesium alloys and other materials. . After a tensile-shear test, four fracture modes were observed: plug . Friction stir spot welding (FSSW) is a very useful variant of the conventional friction stir welding (FSW), which shows great potential to be a replacement of single-point joining processes like resistance spot welding and riveting. . The outputs were selected as the weld’s tensile strength, plunging load, and dwell time. Results suggested .

Friction stir welding (FSW) is a welding technique that involves the application of compressive force to generate heat from the friction between the two end surfaces of the workpieces. . The tensile test followed the ASTM E8 Standard using a 60-ton capacity Hung-ta HT 2101 S tensile testing machine. The tensile test aims to determine a . Herein, microscale tensile testing of the joint interface was coupled with the macroscale fracture evaluation to elucidate the dominant factor of strength in dissimilar joints between 6061 aluminum alloy and high tensile strength galvannealed steel via friction stir spot welding (FSSW).

In the present study, St37 low-carbon steel and 304 stainless steel were welded successfully, with the thickness of 2 mm, by a friction stir spot welding process carried out at the tool dwell time of 6 s and two different tool rotational speeds of 630 and 1250 rpm. Metallographic examinations revealed four different zones including SZ and HAZ areas of St37 . This paper focuses on a comparative study of different ultrasonic feature-based C-scan testing imaging methods for characterizing refill friction stir spot welding (RFSSW) joints, as well as .It was also demonstrated that during the tensile-shear test, the crack originated from the hook defect and failure occurred via pullout mode [28]. . The friction stir spot welding (FSSW) process was capable of mitigating the chemical heterogeneity in the SZ, correlated with the elevated temperature and severe plastic deformation in this . Although the application scope of light metals is expanding to automobiles for manufacturing lightweight vehicles, the demand for steel is still high. Thus, thin-plate and strong high-tensile steel is used in the automotive industry. Recently, friction stir spot welding (FSSW) has come under the spotlight as an alternative to spot welding.

In this study, successful joints were fabricated on 4-mm-thick aluminum alloy 5052 sheets by using friction stir spot welding (FSSW) method. This research thoroughly investigated the impacts of welding parameters, specifically dwell time (DT) and rotational speed (RS), on the microstructure, and joint efficiency mechanical characteristics of the joints. The . Friction Stir Welding (FSW), as a solid-state welding process, can achieve the joining of metals below the melting point or in the plastic stage of the metals with the aid of a non-consumable tool [].Compared with the welds made by fusion welding processes, the friction stir welds have a more homogeneous grain structure and better mechanical properties like tensile . Aluminum alloy is one of the important materials in the field of automotive lightweight research; in order to meet the current demand for welding process of new energy power battery shell, this paper adopts static shoulder friction stir welding (SSFSW) on 3-mm-thick AA3003-H14 to conduct welding test; to explore the influence of welding process . The welding test was carried out using the movable gantry refill friction stir spot welding equipment (FSSW-DLM-204) (Fig. 2a). The welding tool consisted of a stirring pin, sleeve, and clamp ring (Fig. 2b), with diameters of 2.5 mm, 5 mm, and 15 mm, respectively. The rotation speeds were 1500 rpm and 2100 rpm, and the plunge depths were 1.0 mm, 1.5 mm, .

Although the application scope of light metals is expanding to automobiles for manufacturing lightweight vehicles, the demand for steel is still high. Thus, thin-plate and strong high-tensile steel is used in the automotive industry. Recently, friction stir spot welding (FSSW) has come under the spotlight as an alternative to spot welding. The selected range of variables and the chosen tool profile suggest a viable approach for producing friction stir spot welding joints in low-carbon steel and a robustness of the process in achieving an average tensile lap-shear force of 7.48 ± 0.64 kN, surpassing the minimum specification stipulated in the American National Standard AWS D8.1 M .

Download scientific diagram | Experimental Tensile Test Results of Samples for Frication Stir Welding with Different Rotation Speed. from publication: Influence of Temperature on Fatigue Life for .

24 de fev. de 2023 · Check out the new Swarm Season 1 Trailer starring Dominque Fishback! Learn more: https://www.rottentomatoes.com/tv/swa. .more.

friction stir spot welding tensile test|friction stir welding tool material